Case study: Overview of Aludesign’s ESG measures

Aludesign specialises in aluminium die casting and mould production, applied among others in the office furniture, automotive, lightning and railway industries. The Company predominantly caters to foreign customers in Western Europe, with ca. 95% of units exported (the vast majority being delivered to Germany).

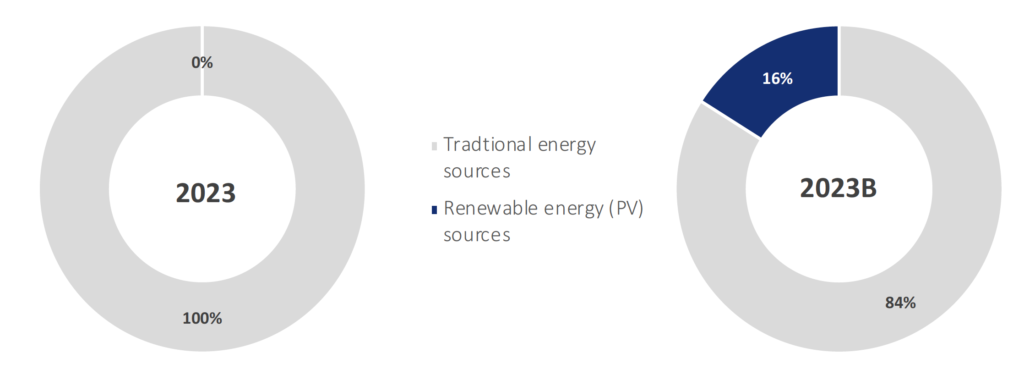

Given the increasing awareness of ESG’s importance in the EU and a growing expectation for sustainable production among its clients, Aludesign implemented a set of environment-oriented measures in recent years, with the most important ones aimed at optimizing its energy consumption levels. This includes i.a. i) building a new production facility equipped with modern energy-saving solutions, ii) purchase of a highly efficient Yizumi 1650 machine (being over 25% more efficient than comparable machines) and iii) setting up proprietary 840 KWp on-premise PV installation, enabling in-house production of energy and reduction of energy levels purchased from external parties. Ca. 16% of the Company’s energy requirement shall be covered internally in 2023B.

In respect to social and governance considerations, Aludesign constantly monitors and improves its health and safety standards through a cooperation with the local unit of the Volunteer Fire Brigade. In addition to cyclical on-site inspections being carried away, the Company provides regular training in the field of fire protection and first aid. Top standards implemented by Aludesign are exemplified by the Company’s no #1 position in the Opole-voivodeship competition organized by the National Labour Inspectorate (the Company also qualified to a national competition combining selected Polish companies with leading health and safety standards).